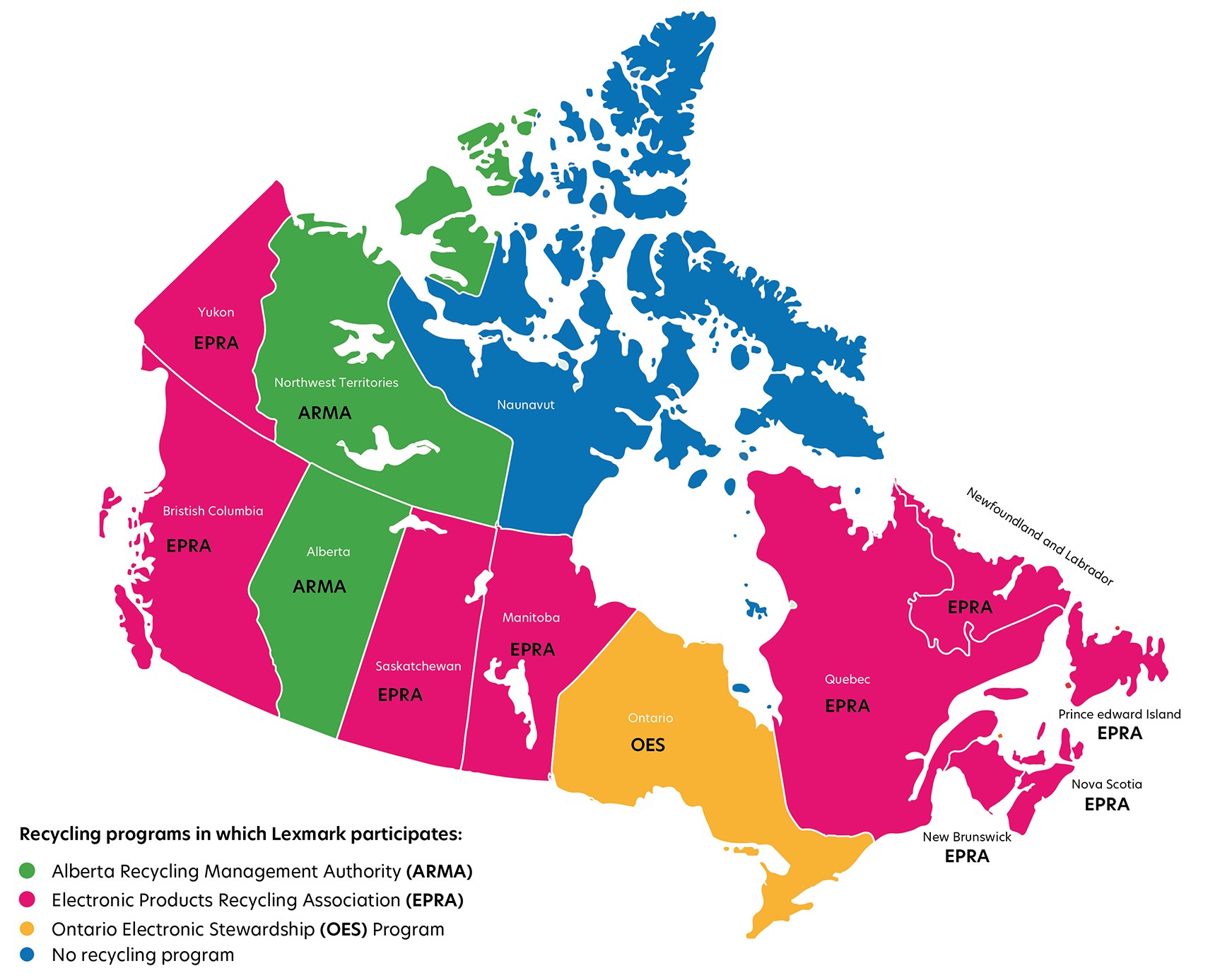

In the United States, we offer the LECP. Through this program, customers may return any end-of-life Lexmark branded products to us, and we recycle the equipment at no charge. For business customers who are in the process of installing a large fleet of new Lexmark products, Lexmark develops customized collection strategies. We work in partnership with certified electronics-disposal agencies to collect used devices, mark them for recycling, and arrange for them to be sent to the nearest recycling facility. Electronic waste legislation has been proposed in a number of states in the United States. There are 14 states and the District of Columbia with enacted extended producer responsibility (EPR) legislation that includes printers: Connecticut, Hawaii, Illinois, Maine, Michigan, Minnesota, New Jersey, New York, North Carolina, Oregon, South Carolina, Utah, Vermont and Wisconsin. While the details of the legislation vary greatly from state to state, the basic tenet is that the producers of electronic devices are required to collect and responsibly recycle covered electronic devices at the end of the devices’ usable lives.

A Lexmark printer hardware packaging return program is also in place in the U.S. Packaging material from Lexmark hardware including service parts may be returned to Lexmark for recycling. Customers may use their new printer’s packaging material to return their old Lexmark printer or they may return only the packaging material from their printer or hardware to Lexmark. For more details, click here.