Lexmark changes the way we use resources by putting returned material back into products instead of into landfills. Since 2004, Lexmark has redirected over 150,000 metric tons of material away from landfills using our Lexmark Cartridge Collection Program (LCCP). Cartridges returned by our customers to our LCCP facility are easily disassembled for possible reuse or remanufacturing. If remanufacturing is no longer an option, the cartridge is recycled.

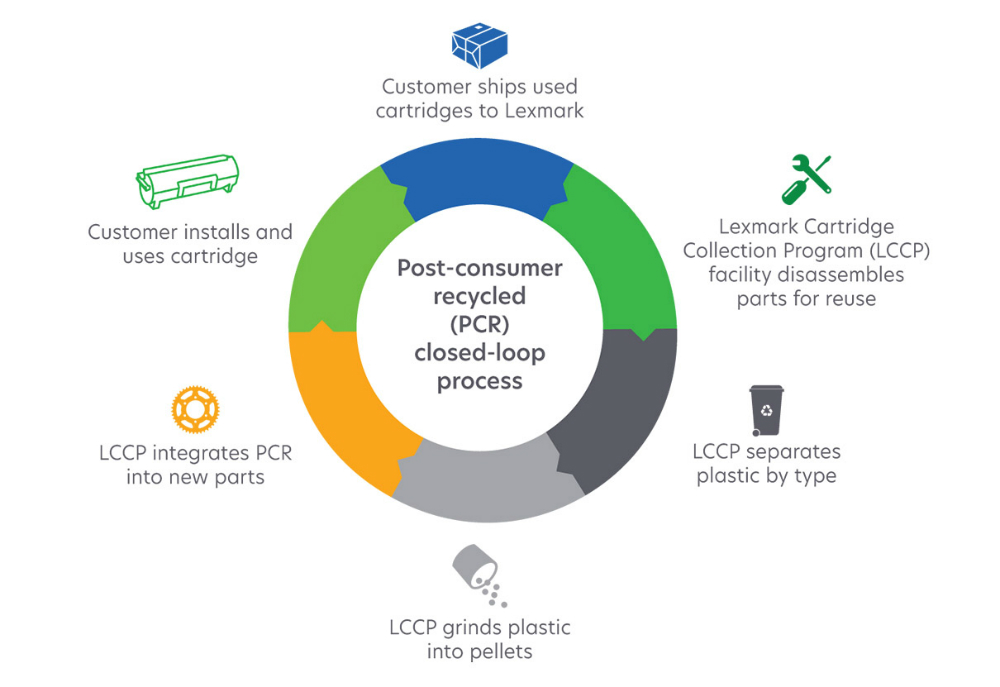

Lexmark engineers reclaim post-consumer recycled (PCR) plastic from cartridges and return the material to near virgin quality for use in printer components. The ingenuity behind our PCR closed-loop process involves every production step taking place at our LCCP facility in Juarez, Mexico. Our closed-loop recycling system removes the plastic, grinds it, and then integrates the PCR plastics into new parts.

Since 2015, 26,357 metric tons of plastic were collected at our global LCCP facilities from our used cartridges with 15,587 metric tons reused in new products and 10,771 metric tons recycled. All plastic collected from the LCCP is reused or recycled preventing 100% of the plastic from ending up in landfills, incinerators or being used as waste-to-energy.

Lexmark is an industry leader in the use of reclaimed plastic in our products. 100% of our hardware product offering contains some PCR content and 69% of the models contain over 30% PCR content. Conserving plastics for reuse demonstrates Lexmark’s commitment to the environment and helps our customers reduce their carbon footprint. Lexmark is consistently recognized around the globe for our sustainability leadership and our customers site this commitment as a key factor in doing business with us.