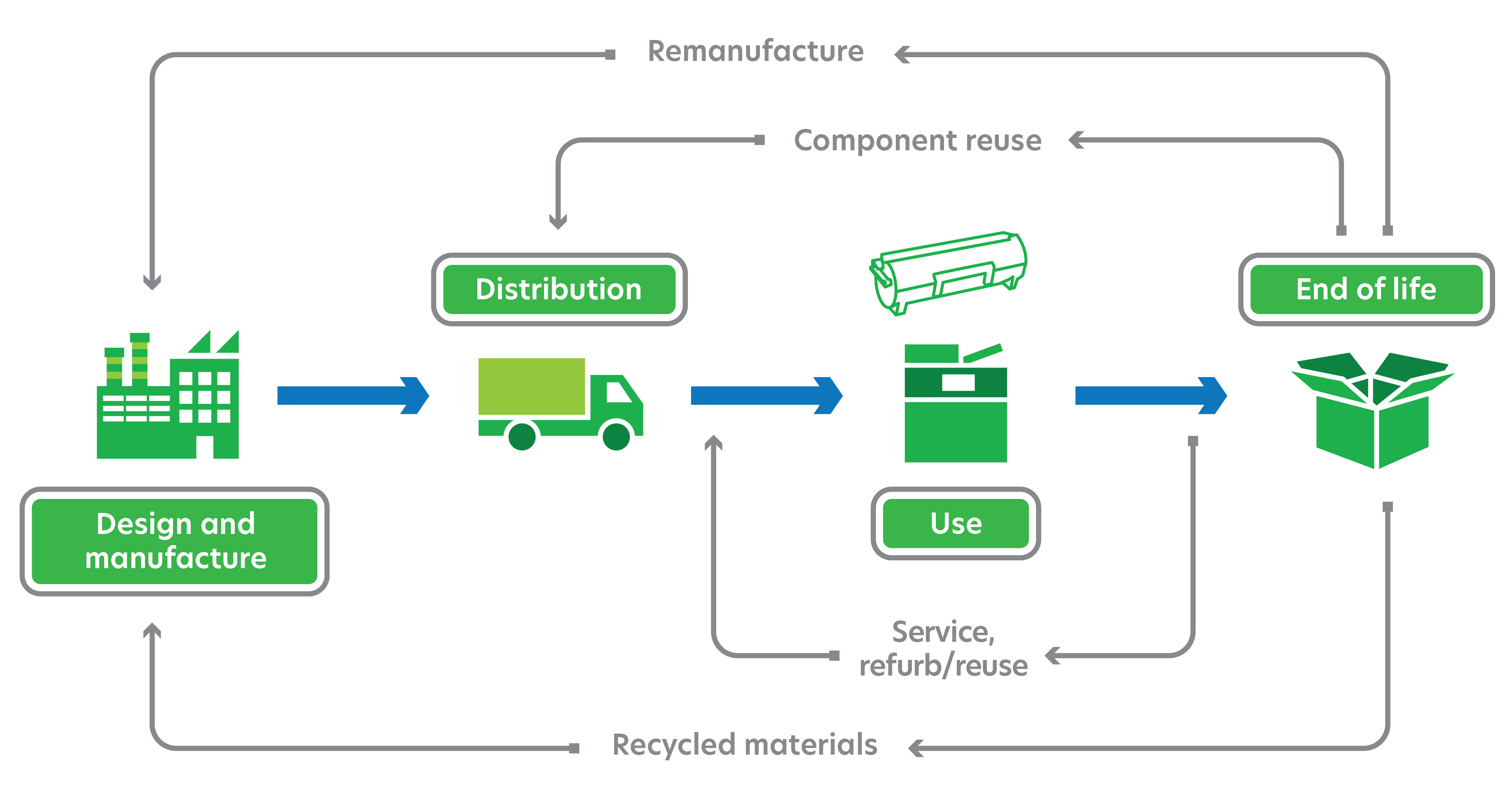

At Lexmark, we look at the environmental impact of our products throughout their life cycle. We see where we can deliver optimal environmental performance by incorporating innovative circular design concepts and material improvements. Our intentional design efforts yield high quality, long-lasting products that are not only reusable and recyclable,1 but also incorporate recovered materials.

Lexmark's circular journey began over 30 years ago with the incorporation of PCR plastic in the Optra series of printers. As the availability of PCR plastic in the market increased, we began to offset virgin resin by boldly pursuing recycled options.

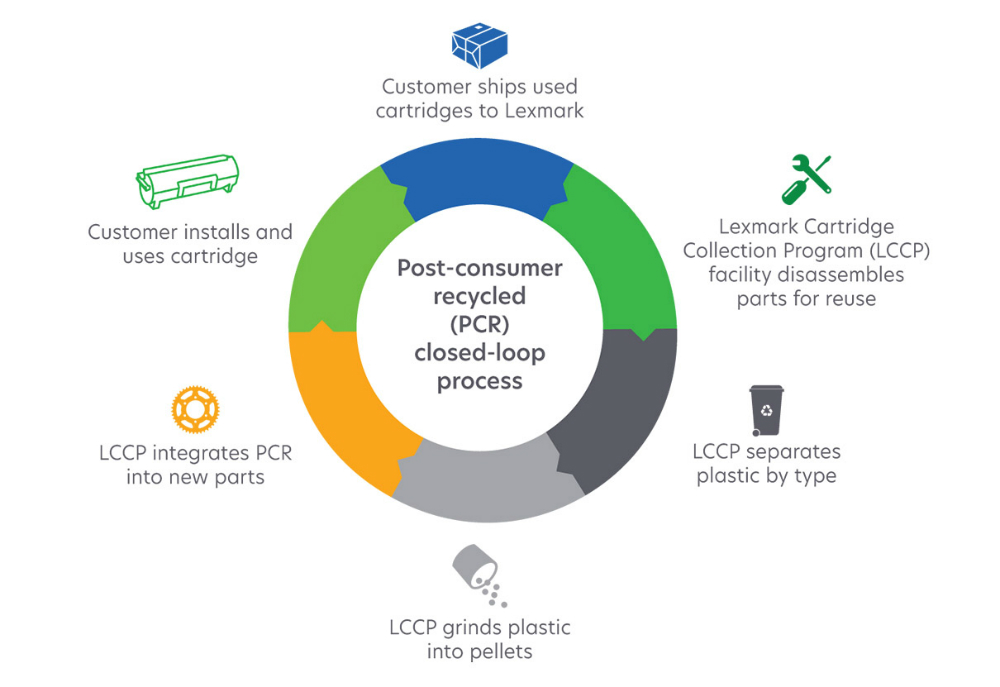

Lexmark's award-winning Lexmark Cartridge Collection Program (LCCP), established to keep our cartridges from ending up in a landfill, became an opportunity to further offset the use of virgin materials via cartridge remanufacturing. Materials unable to be directly reused were recycled.

Seeing the value in closing the materials loop, the LCCP facility began to utilize the materials from the returned cartridges back into our own products for a true closed-loop process. Our engineers innovated our own in-house extrusion and compounding process to produce high quality, 100% recycled resin that is reintegrated into new toner cartridges. Underwriters Laboratory (UL) certified our PCR resin for use at a rate of 100% for print cartridge components in 2016, making it the first UL-certified 100% recycled resin to be processed in-house by Lexmark. In 2022, 100 metric tons of PCR plastic material were processed. We have qualified over 145 components with up to 100% closed-loop PCR plastic.

Lexmark prioritizes reusing components over recycling in alignment with the EPA's waste management hierarchy. Lexmark is an industry leader in the use of reclaimed plastic with 41% of the plastic content, by weight, across all Lexmark designed toner cartridges coming from post-consumer plastic. In fact, 80% of this reclaimed plastic is from remanufacturing reuse, with 10% coming from the LCCP PCR feedstream and 10% from purchased PCR resin. Our goal is to increase the use of reclaimed plastic in Lexmark branded and designed cartridges through the PCR and product reuse processes to 50% by 2025.

Lexmark prioritizes reusing components over recycling in alignment with the EPA's waste management hierarchy. Lexmark is an industry leader in the use of reclaimed plastic with 41% of the plastic content, by weight, across all Lexmark designed toner cartridges coming from post-consumer plastic. In fact, 80% of this reclaimed plastic is from remanufacturing reuse, with 10% coming from the LCCP PCR feedstream and 10% from purchased PCR resin. Our goal is to increase the use of reclaimed plastic in Lexmark branded and designed cartridges through the PCR and product reuse processes to 50% by 2025.

In the future, we plan to incorporate closed-loop recycled materials from our hardware recycling streams into new devices in much the same way we are doing for cartridges. To help prepare for this content, Lexmark has been utilizing greater amounts of recycled plastic in our printers, with some models qualified to include up to 60% PCR by weight of plastic.2

Lexmark uses several suppliers who declare their base resins are sourced from 100% post-consumer waste electrical and electronic equipment (WEEE). Our use of PCR sourced from used electronics provides incentive to electronics manufacturers and recyclers to continue to grow the circular economy in this industry.

Lexmark branded, in-house designed laser printer and multifunction product hardware models sold in 2022 contain an average of 40% PCR plastic by weight of plastic,3 with 100% of these models containing some PCR plastic content. An estimated 2,300+ metric tons of post-consumer recycled plastic was used in the manufacture of the 2022 branded, in-house developed printers and MFPs. Our goal is to increase the average post-consumer recycled content plastic in Lexmark branded and designed models to 50% by 2025.

Currently, we favor the use of post-consumer recycled (PCR) materials over the use of bio-based materials for durability and recyclability.

The metal content in Lexmark printers is dominated by steel products, primarily used for the sturdy steel frames, that provide extended product life. Published industry averages indicate that commercial grades of steel commonly contain between 30% and 80% recycled content.

Recyclable design

Over 90% of the materials used in hardware products by weight are recyclable.1 Most of these materials are polymers and metals that are formed into components through injection molding or stamping operations. Lexmark used an estimated 5,800 metric tons of plastic in our 2022 hardware models, with acrylonitrile butadiene styrene (ABS) comprising 59% of that volume, followed by high-impact polystyrene (HIPS) at 12%, polycarbonate/ABS blend and acetal (POM) at 9% each. 3,180+ metric tons of steel were used in Lexmark branded hardware. Our cartridges are primarily comprised of the same materials as the hardware and are designed for zero waste to landfill.

Our materials management approach is broad, ranging from our focus on materials used and sourced from our suppliers, to our active participation in industry trade associations.

Lexmark’s Corporate Sustainability team is responsible for maintaining the Product Environmental Specification. Lexmark's Product Environmental Specification defines the minimum environmental requirements associated with the design, manufacture, and marketing of Lexmark products. The criteria stem from global regulatory obligations, international treaties, and conventions to specific market demands. The team reviews the Product Environmental Specification annually to include the latest regulatory references.

The Lexmark Product Environmental Specification is available online for access at any time. We also provide it to suppliers in contract terms and to material suppliers during the development process. Lexmark audits select suppliers for compliance to the Lexmark Product Environmental Specification during the delivery of parts and assemblies.

To support materials management efforts, Lexmark maintains an annual materials content data collection and management system. This system allows our teams to address regulatory issues, communicate with suppliers about substances of concern, and respond to customer questions.

Restriction of hazardous substances

Lexmark evaluates printers, supplies and packaging for compliance with material restriction directives and legislation. Lexmark complies with the material restriction requirements adopted under the European Union's Recast of the Restriction of Certain Hazardous Substances (RoHS) in Electrical and Electronic Equipment Directive 2011/65/EU as amended by EC/2015/863. Per the RoHS recast directive, conformance is declared via the CE Mark declarations, which are posted on the Lexmark website: Regulatory Compliance.

RoHS restricts the amount of certain hazardous substances in electrical and electronic equipment. These hazardous materials include four metals (lead, mercury, hexavalent chromium, cadmium), two brominated flame retardants (polybrominated biphenyl and polybrominated diphenyl ether), and four phthalates (DEHP, BBP, DBP and DiBP). Lexmark does not claim RoHS exemptions for cadmium or mercury. Lexmark has developed a conformance assurance system for materials restrictions that includes an annual audit process. Audit results indicating a nonconformance lead to further evaluation, material or component changes if needed, and notification to authorities if products ship with noncompliant parts. Information on conformance may be found in Product Health and Safety.

Lexmark works with our suppliers to ensure compliance with international material restriction regulations such as the European Union Registration, Evaluation, and Authorization of Chemicals (REACH) regulation. REACH seeks to improve public health and the environment by controlling the production and use of harmful chemical substances. Lexmark completed the first steps of REACH in 2008, including preregistration, material review and required communications for the initial release of the Substances of Very High Concern (SVHC) candidate list of chemicals. Lexmark continues to monitor REACH developments and the addition of new chemicals to the SVHC list and comply with chemical registration and legal obligations imposed.

Please see the REACH position paper for more information.

In compliance with the Montreal Protocol, Lexmark prohibits the use of ozone-depleting chemicals in the manufacture and development of our products.

Cartridges deliver toner used in the printing process. Lexmark toners are classified according to the Globally Harmonized System of Classification and Labelling of Chemicals (GHS). At the cartridge level, Lexmark toners are not classified as hazardous chemicals. In the United States, GHS regulations classify toner in bulk container form as a combustible dust; however, Lexmark toners are not classified as hazardous outside the United States. Lexmark provides Safety Data Sheets (SDSs) for these toners, where applicable safe handling and health analyses can be found.

Current SDSs are available on the Lexmark website.

1 Based on data and available recycling streams from our recycling partner, Sims. Click here to learn more.

2 PCR calculated using IEEE.1680.2 methodology

3 Based on the post-consumer recycled materials used in Lexmark’s primary imaging equipment sales for 2022 Lexmark branded, in-house technology. PCR calculated using IEEE.1680.2 methodology.