Lexmark has conducted Life Cycle Assessments (LCAs) on 92 of its printer and MFP models by the end of 2022 and is committed to performing LCAs on future product models.

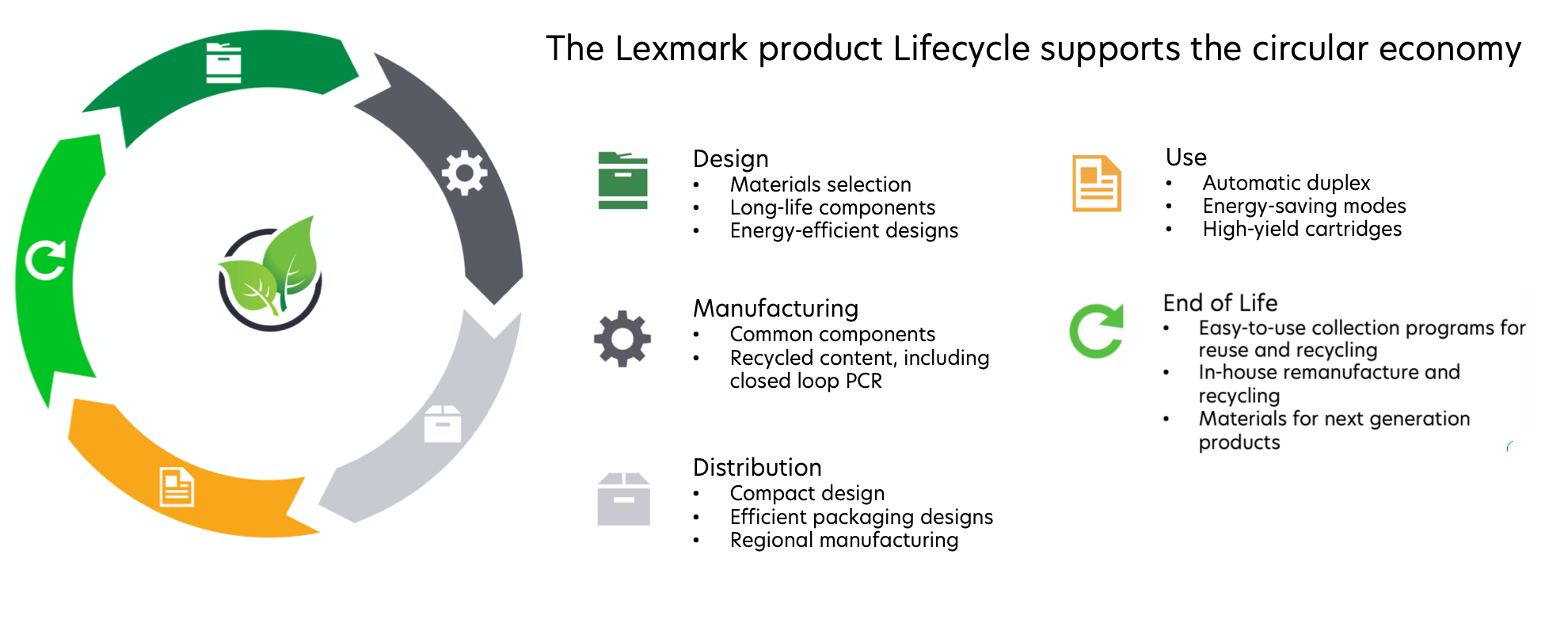

LCAs technically evaluate the environmental phases of the product design, manufacturing, distribution, use and end-of-life of our products. Lexmark is continuing to improve accuracy and transparency of our LCAs by working with an external consultant to include all possible phases of the printer life cycle and ensure our electronics are counted and scaled accordingly.

The data from the LCAs is used to create and publish ISO 14025 Type III Environmental Product Declarations (EPDs), which summarize the complex information provided by the assessment. Each EPD conforms to the international standards ISO 14040:2006, ISO 14044:2006 and ISO 14025:2007 and follows the requirements of the Product Category Rules (PCR) for preparing an EPD for Printers and Multi-function Printing Units published by UL Environment (ULE). Lexmark is using the latest edition of PCR published April 23, 2018 for products announced in 2018 and beyond.1 The EPDs are third-party certified for accuracy and completeness.

For information on secondary sources used in the LCAs, see Life Cycle Assessments Data.

The LCA reports have identified the use phase as having the greatest impact in the life cycle of the Lexmark printer—in particular, paper. This learning has shaped Lexmark’s focus on offerings to help customers print efficiently, optimize print environments, and return hardware and consumables at end of life.

Lexmark works to reduce the environmental impact of paper by providing customers choices when it comes to printing. One way we achieve this is by testing products to ensure recycled paper may be used—specifically, papers made with 30%, 50%, and 100% post-consumer recycled content. Our expectation is that recycled papers perform as well as virgin paper in our printers. While no official standard exists for office equipment use of paper, Lexmark uses European Standard EN 12281 as a minimum properties standard. To ensure breadth of testing, test paper includes 100% recycled papers from North America, Europe, and Asia, and tests are conducted at 8-80% relative humidity. Testing includes duplex printing. Office paper using renewable, recycled, or chlorine-free content may all be used.

Lexmark printers are also designed with features such as duplex and multi-page printing to minimize the number of pages needed in a print job. Options such as Scan to E-mail and Print Release further provide customers with ways to increase efficiency and reduce printed pages.

Additionally, Lexmark has partnered with PrintReleaf, a company that utilizes its patented software platform that empowers businesses to sustain and grow our global forestry system. PrintReleaf's technology integrates with our print management software to measure paper consumption data. This information is converted into an equivalent number of trees, which are then planted in specific global reforestaion projects. These projects are designed to rebuild negatively impacted or endangered forests and help counter the impacts of paper consumption.

Looking beyond the impact of paper in the life cycle assessments, consumables, energy, and printer maintenance actions are highlighted as areas for improvement. Lexmark devices are intentionally designed to last seven years or more. Lexmark has dedicated teams working on product energy reductions, consumable sustainability and end of life recycling and remanufacturing, as well as longevity of components and proactive printer maintenance to extend product life. When we compare products generation to generation we see improvements in these areas.

Lexmark has also pursued cartridge LCAs to identify areas where improvements can be made within the cartridge life cycle. Conducted in accordance with ISO 14040 and 14044, the Lexmark LCA cartridge studies showed that recycling a used Lexmark toner cartridge reduces the carbon footprint of the cartridges studied by nearly 50% over discarding it in a landfill, consistently confirming the value of the LCCP operations and efforts to increase cartridge collections. This value excludes paper consumed when printing.

1 Products announced prior to 2018: Product Category Rules for Printers and Multi-Function Printing Units, UL Environmental Standard, Edition 1 (Dec 12, 2012)