Lexmark continues to focus on maintaining efficient use of natural resources at our leased and owned manufacturing facilities, research and development facilities, and office spaces worldwide, tracking data since 2005 and meeting aggressive goals. In 2015, we set a goal to reduce energy consumption 20% by 2025, at the end of 2022, we achieved a 26% reduction. Lexmark continues to initiate multiple approaches to ensure company-wide goals are met. We are focused on appropriate and meaningful projects at each location. Lexmark is committed to carbon neutrality by 2035. After achieving this, we will work toward our goal of net zero carbon emissions by 2050. Reaching this goal is highly dependent on the development of new emission reduction, removal and capture technologies.

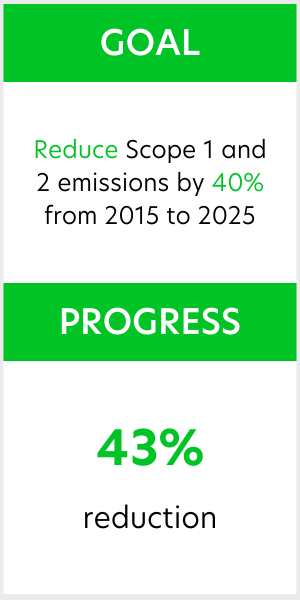

We have been focused on a previous goal to decrease Scopes 1 and 2 emissions by 40% from 2015 to 2025. At the end of 2022, we had a reduction of 43%. As we continually aim to aggressively reduce our operational energy consumption, we set a near-term science based emissions reduction target. We are committed to reduce absolute scope 1 GHG emissions 27.5% by 2030 from a 2019 base year.

Lexmark engaged SGS to conduct an independent verification of Scope 1, Scope 2 and limited Scope 31 GHG emissions.

As we continue to drive our emissions and energy consumption to minimal levels with efficiency projects, we will also utilize renewable energy, carbon credits and renewable energy certificates (RECs) to offset emissions.

We created a goal to increase annual sourcing of renewable energy to 100% by 2030. In 2022, Lexmark broke ground on a two-megawatt solar array installation on headquarters property in Lexington, Kentucky. Residing on a brownfield the solar array location has been seeded with native pollinator plants, which will require little maintenance and will benefit the local ecosystem in several ways. The solar array is expected to produce enough renewable energy to achieve a 10% reduction in the carbon footprint for the Lexington site. Similar renewable energy production projects are being considered at other Lexmark locations. A pilot project of 3.2 kilowatt solar array system was installed on the rooftop at one of the Cebu, Philippines office buildings. We procured 29,335 MWh of Renewable Energy Certificates (RECs)2, 22% of our 2022 total scope 2 emissions.

With the exception of third party steam used for heating our Boulder, Colorado site, Lexmark operations use electricity as its one indirect energy source. We primarily purchase electricity from local energy providers from local grids. The electricity supplied is generated by a variety of nonrenewable and renewable primary energy sources, including coal, nuclear energy, solar power, wind power, geothermal energy and hydropower.

Lexmark's direct energy sources include: natural gas, diesel fuel and gasoline. These nonrenewable energy sources are purchased from local vendors and then used to generate steam, power backup generators, provide heat to certain Lexmark facilities and provide fuel for leased/owned vehicles. We do not use renewable direct-energy sources such as biofuels (ethanol for example) or hydrogen.

In 2022, working with Climate Impact Partners, we announced our first certification targeting climate action, our Juárez, Mexico facility is now CarbonNeutral® manufacturer certified. Third party certification is our method to achieving carbon neutrality. Through planning, efficiency projects and sustainability strategies applied to daily work and an investment in certified projects to offset the remaining greenhouse gas emissions. Also in 2022, Lexmark announced its first CarbonNeutral® product certification for two devices.

Energy conservation is a priority in the workplace, through simple practices of improving lighting, electronics and equipment and powering off when not in use and using schedules and sensors for lighting and temperature control. These and many other initiatives assist in meeting targets. Some of our employee incentive programs include site energy reductions, which include monetary incentives for emplooyees when the overall annual energy goal is achieved. In addition to salary incentives, some of our sites promote employee energy awareness through healthy living and sustainable challenges, which provides monetary incentives for various levels of challenge participation.

Click here for detailed GHG emissions data.

Solar flower located at Lexmark headquarters, Lexington, Kentucky

Solar flower located at Lexmark headquarters, Lexington, Kentucky

Green house gas emissions is a key focus for Lexmark throughout our valuechain. We are committed to taking aggressive actions and making meaningful reductions. In 2023, our targets for scopes 1, 2 and 3 (shown below) received validation from Science Based Targets Initiative (SBTi).

We are conscious of the impact business travel can have on the environment and avoid it when possible with the use of lower impact, real time communication tools. We have collaborated with our vehicle and travel partner to calculate miles traveled with Lexmark-owned, -leased, and -rented vehicles, as well as air travel.

Lexmark France participates in the BlueBiz CO2ZERO program. Through this program, companies can cash in blue credits earned from employee travel with Air France, KLM or Delta Air Lines to neutralize CO2 emissions of their flights. Lexmark's contribution helps with planting new trees, maintaining existing forests and supporting local communities in Panama through the reforestation project CO2OL Tropical Mix―offsetting 143.2 metric tons of CO2 to date.

Many Lexmark positions are open to Flex@Lexmark, giving employees the ability to work remotely two days a week. Susatainable commuting is encouraged. Biking to work is promoted at many Lexmark locations. Bike racks and showers are availble and indoor storage is an option at some locations. Challenge programs are available with opportunities to earn prizes and money for biking to work and or carpooling. Lexmark's site in Boulder, Colorado works with Smart Commute Metro North to promote alternative commuting options for employees such as ride sharing and transit travel. In Lexington, the public bus stop is located on the campus parking lot.

Four electric car charging stations are in use at the Lexington, Kentucky campus. Each station is equipped with two charging points for registered employees and clients to use free of charge. In 2022, 17.3 metric tons of GHG were avoided and 48.1 metric tons of greenhouse gas emissions have been avoided since installation. Two charging stations are in use at Boulder, Colorado's campus.

Physical worldwide shipping, handling and processing of products and distribution centers are a necessary part of Lexmark business. We have taken measures to lessen the environmental impacts associated with these activities and work with environmentally progressive partners who apply innovative ideas, best practices and new technologies to their transportation and logistics processes. Lexmark is working to quantitatively report the impact of product logistics.

We test our products throughout their life cycle to ensure high quality. Realizing the impact of paper use on the environment, we are working to lessen this impact in our print testing. We use “paperless print” for some testing applications, which allows us to test certain features of our product without actually printing the page. We also reuse paper where possible. These methods of print testing helped us save over 4,360 trees3 in 2022 and avoid over 1,696,000 kg of CO2.

The service delivery team at Lexmark proactively identifies issues with devices under contract, often providing a fix before a service intervention is required. If a call is made to our technical support center, priority is placed on resolving the problem via phone versus dispatching a technician. If a part is required to fix the issue and can be replaced by the customer, technical support will provide step-by-step instruction or support resrouces, such as video, to help with replacement. Many teams and projdects are focused on ensuring that correct parts are sent and unnecessary parts dispatch is avoided. Our focus on "remote fix" and parts accuracy helps reduce wasted resources, such as materials for parts manufacture, mileage associated with parts delivery and onsight service visits. This results in improved customer satisfaction and avoidance of GHG emissions.

Click here for detailed regulated air emissions data.

1 Only 10 of the 15 Scope 3 Categories apply to Lexmark's business. Four categories (3,5,6,7) are included in our 3rd party verification for CarbonNeutral Protocol.

2 The RECs procured consist of Mexico I-RECs to offset Juarez, Mexico site's scope 2 and US Green-eRECs making up 13% of the Lexington site scope 2.

3 Environmental impact estimates were made using the Environmental Paper Network Paper Calculator Version 4.0. See www.papercalculator.org.