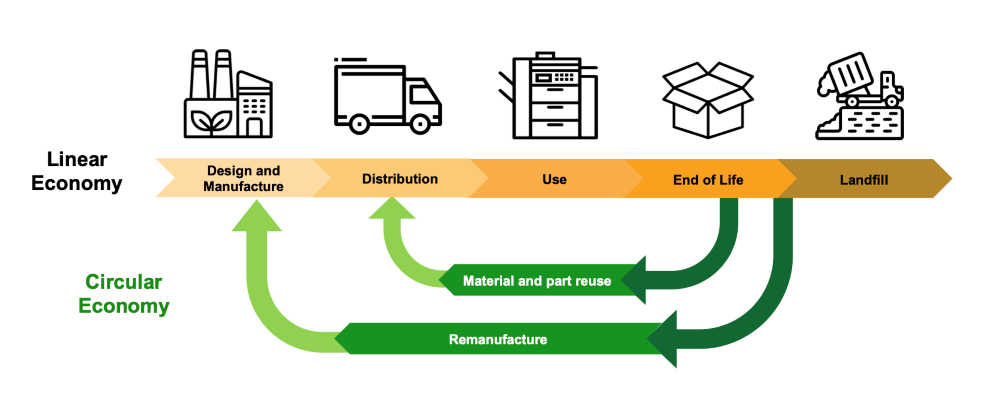

Lexmark has been in support of the circular economy and remanufacturing initiatives since our inception 30 years ago. In 1991, we began reclaiming material through our Lexmark Cartridge Collection Program (LCCP), and we have been creating post-consumer recycled (PCR) plastic in our closed-loop process for 11 years. As a leading remanufacturer, we understand that the adoption of circular economy principles promotes innovation and economic growth in a more environmentally sustainable manner.

Our founding membership in the European Remanufacturing Council (CER) provides Lexmark with the opportunity to share with other businesses how to extend product life and retain valuable materials. As a member of CER, we seek changes to policy with the aim of making remanufacturing a normal part of a product life cycle. Members of the CER aim to triple the value of Europe’s remanufacturing sector to over $100 billion by 2030.

Design for long life and durability

Lexmark makes a clear choice toward planned durability, intentionally engineering long-life devices designed to last seven years or more. Device life is extended further through remanufactured and repaired parts and supplies. Longer-life devices save finite resources, reduce waste going to landfills and lower carbon emissions. Preserving resources and reusing materials have been important to Lexmark since our inception. We have reused over 34 million kilograms of recovered cartridge materials since 1996 by converting millions of used toner cartridges into Lexmark-certified remanufactured toner cartridges. For more information on how Lexmark designs our products for extended life, click here.

Industry leadership

Lexmark actively works with many stakeholders, partners, industry groups and governing bodies to rethink and redesign our products in the framework of a circular economy. Lexmark participated in impactful sustainability initiatives and projects with other industry leaders. Our partnerships with companies committed to advancing the circular economy provided us with the expertise to conduct internal projects that reduce waste and promote the long-term use of resources. At Lexmark, global cross-functional teams from over 20 areas of the business incorporate circular design into our products and maximize their life cycle by offering robust take-back and remanufacturing programs.

Our commitment to remanufacturing is recognized by prominent supporters of sustainable manufacturing. Our endeavors most recently resulted in an EcoVadis Platinum medal, the highest level of this extra-financial assessment. EcoVadis has grown to become the world’s largest and most trusted provider of business sustainability ratings, creating a global network of more than 100,000 rated companies and their supply chains to assess their performance in the field of corporate social responsibility (CSR) and governance. Lexmark is in the top 1% of all companies assessed and a clear leader in our sector. Since 2014, Lexmark has consistently received high EcoVadis ratings.

Lexmark also received the ISRI 2020 Design for Recycling Award for our toner cartridge design and recycling process. Additionally, Lexmark received Manufacturing Leadership awards in sustainability leadership for reuse and remanufacturing efforts. See more about Lexmark awards and recognitions here.

EU research and innovation projects

To assist our innovative efforts in remanufacturing and to promote a circular business model, the European Union Framework Program for Research and Development awarded Lexmark funding for three projects, C-SERVEES, DiCiM and CE-RISE, to build circular economy solutions for the global market place.

Lexmark received a Horizon 2020 research and innovation grant under agreement Nº 776714 to participate in the C-SERVEES project. Selected from over 100 applicants, Lexmark worked with other C-SERVEES project participants for four years to develop an innovative circular economic business model for the electrical and electronic (EE) sector. C-SERVEES results revealed the importance of determining the end-of-life material recovery yield of EE equipment, recovering valuable materials through easy dismantling and providing a digital disassembly instruction manual through a QR code. Environmental impact is reduced, and circularity of the product is enhanced through novel tools to track material data and product characteristics for effective remanufacturing of products. For more information on Lexmark's contributions to the C-SERVEES project, click here.

Digitalized Value Management for Unlocking the potential of the Circular Manufacturing Systems with integrated digital solutions (DiCiM)

Lexmark is one of 12 consortium partners from nine countries in the €6 million EU budget DiCiM project. DiCiM is dedicated to utilizing digital tools to accelerate circular economy business models. The project will develop integrated digital solutions that make use of Internet of Things (IoT), Machine Learning (ML) based Artificial Intelligence (AI), Big Data, Image Processing and Augmented Reality (AR).

As the only print manufacturer participating in DiCiM, Lexmark (specifically Lexmark Belgium, Lexmark España and Lexmark Hungary) will assist the DiCiM project with IoT monitoring and identifying the key parameters in real time. This will include implementing an open access digital platform and demonstrating the capability of the printers for enabling tracking, tracing, and condition monitoring. For more information on Lexmark’s contributions to the DiCiM project, click here.

The CE-RISE project involves 22 partners from 12 countries with a €7.6 million EU budget. It aims to lead research into sustainable models and take them one step further by maximizing the use of secondary raw materials (SRMs) and utilizing IoT and AI approaches. CE-RISE will foster a dynamic ecosystem geared toward prolonging the use of materials in the economy while Lexmark will contribute to pilot studies, create prototypes and gather information for a Digital Product Passport (DPP) which will enable the traceability of materials in the supply chain. The eventual aim will be to provide stakeholders with a better understanding of the green credentials of electronic products and educate the industry on how to preserve important raw materials throughout the reuse, repair and recycling of these items. For more information on Lexmark's contributions to the CE-RISE project, click here.

Lexmark has taken a proactive position to help consumers make informed and sustainable decisions. We offer a broad digital passport for our product lines with key environmental information in support of the circular economy. The Lexmark Digital Passport can be referenced with information such as product buying guides, providing repair and recycling options, lifecycle analysis, and material selections.

To encourage the use of recycled plastic, Lexmark accepted the European Commission’s call for action in Annex III of the European Strategy for Plastics. Lexmark is one of the initial 70 companies and businesses voluntarily pledging to use more recycled plastics in Europe and to ensure by 2025, 10 million tons of recycled plastics find their way into new products.

Lexmark is an industry leader in the use of reclaimed plastic with 41% of the plastic content, by weight, across all Lexmark designed and branded toner cartridges, derived from postconsumer sources, including our own LCCP closed-loop process. Of the LCCP reclaimed plastic used, 80% is from remanufacturing reuse, with 10% from the LCCP PCR feedstream and 10% from purchased PCR resin. Lexmark’s goal is to increase the use of reclaimed plastic through the PCR and reuse processes by 50% by 2025.

Over 90% of the materials by weight used in our Lexmark designed and branded hardware products are recyclable.1 Today, 100% of our total product offering contains some PCR content with almost 70% of the models containing over 30% PCR content with almost 70% of the models containing over 30% PCR content. Continual reuse of recycled materials greatly reduces the amount of waste sent to landfills. Click here to learn more about Lexmark's use of PCR.

Electronic precious metals recovery

Lexmark continues to explore the recovery of precious metals to enable clean, domestic recycling of sorted electronic waste through the chemical extraction of precious metals (primarily copper and gold). Recovering valuable materials from end-of-life devices and recycling them into new products expands Lexmark’s leadership in the circular economy movement.

Data analytics accelerates the circular economy

Leveraging Lexmark data analytics, companies have visibility of the location and condition of their products to continuously monitor performance. Having access to real-time data enables detailed tracking of devices and supplies to ensure efficient use of Lexmark’s long-life products. Lexmark manages over one million devices in more than 2,000 locations around the world with over 10 terabytes of data analyzed weekly. Maximizing and extending the life of our products provide our customers with the opportunity to operate more sustainably.

As part of the EU-funded C‐SERVEES project, Lexmark is working on a private blockchain data scheme. The data provides a reliable system for sustainable material optimization throughout the stages of the circular economic process (origination, manufacturing, recycling, transportation and use phase). Artificial intelligence (AI) may also be used to better predict product performance, reliability and lifecycle analysis.

Remanufacturing role model

Lexmark helps our customers print sustainably by using a combination of new and reclaimed components to minimize their environmental footprint. Designed and developed for maximum sustainability benefits, Lexmark’s Corporate Cartridge product line is guided by the principles of zero waste and a circular economy. The Corporate Cartridge closes the loop through the incorporation of components returned via the LCCP.

Cartridges returned to our manufacturing facilities through our LCCP are disassembled, components are evaluated for reuse then selected and incorporated into the production system of the Corporate Cartridges. Innovative processes created by our engineers recover postconsumer recycled (PCR) plastic and pelletize the PCR for integration into new components. Reclaimed PCR plastic is qualified in over 145 Lexmark components at a level up to 100% PCR plastic.

Since 1991, Lexmark has redirected over 160,000 metric tons of material away from landfills using LCCP. In 2022, through the efforts of our customers, 36% of the total Lexmark branded and designed toner cartridges shipped worldwide were returned through the LCCP. In some regions, the return rate was even higher. The United States continues to average approximately 50% return rates and we estimate the industry average collection rates to be 20-30%.

Devices returned to Lexmark go through a process that assesses if they can be remanufactured for reuse. If not reused, parts are harvested for the refurbishment process. Lexmark works with recyclers to reclaim parts that can be used to refurbish printers, which keeps the printers in service longer and reduces the need to recycle used hardware.

Continually improving the way we do business

Lexmark affirms our commitment to designing out waste and pollution through collaboration with organizations supporting the circular economy business model. Company-wide innovation has led to the discovery of reuse and recycle techniques novel to our industry. Lexmark strives to minimize waste while maximizing resource efficiency through remanufacturing and empowering our customers to protect natural resources by joining our efforts. Click here to learn more about Lexmark’s Product Sustainability.

1 Based on data and available recycling streams rom our recycling partner, Sims. Click here to learn more.